Material testing with exceptional precision

The parts we inspect hold together products like cars and jet engines.

Technomix AG is a specialist in non-destructive visual and dimensional inspections and material testing, as well as destructive hardness tests using the Vickers method.

Manufacturing companies of all kinds rely on our expertise for definitive, safe evaluations of the quality and condition of their products. We have the equipment necessary to test even the most complex microparts.

Comply with agreed contract terms, prevent returns and economic risks and secure your reputation both on the market and among your clients.

Technomix can identify even the smallest damage and inconsistencies.

What can we focus on for you?

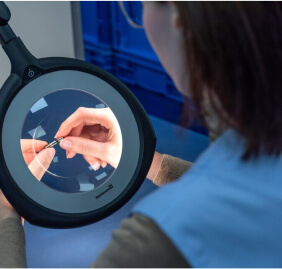

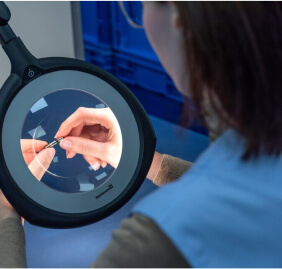

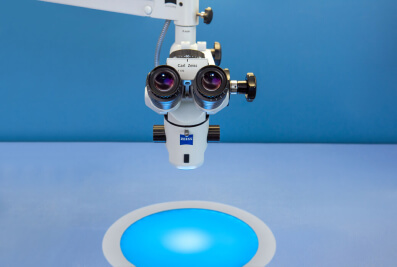

Visual inspection

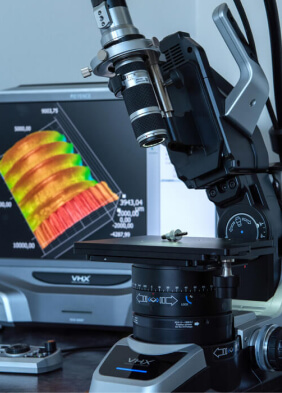

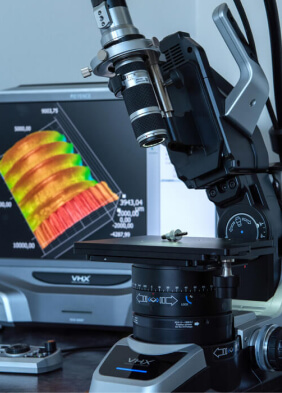

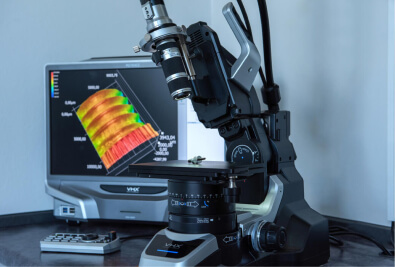

Dimensional inspection

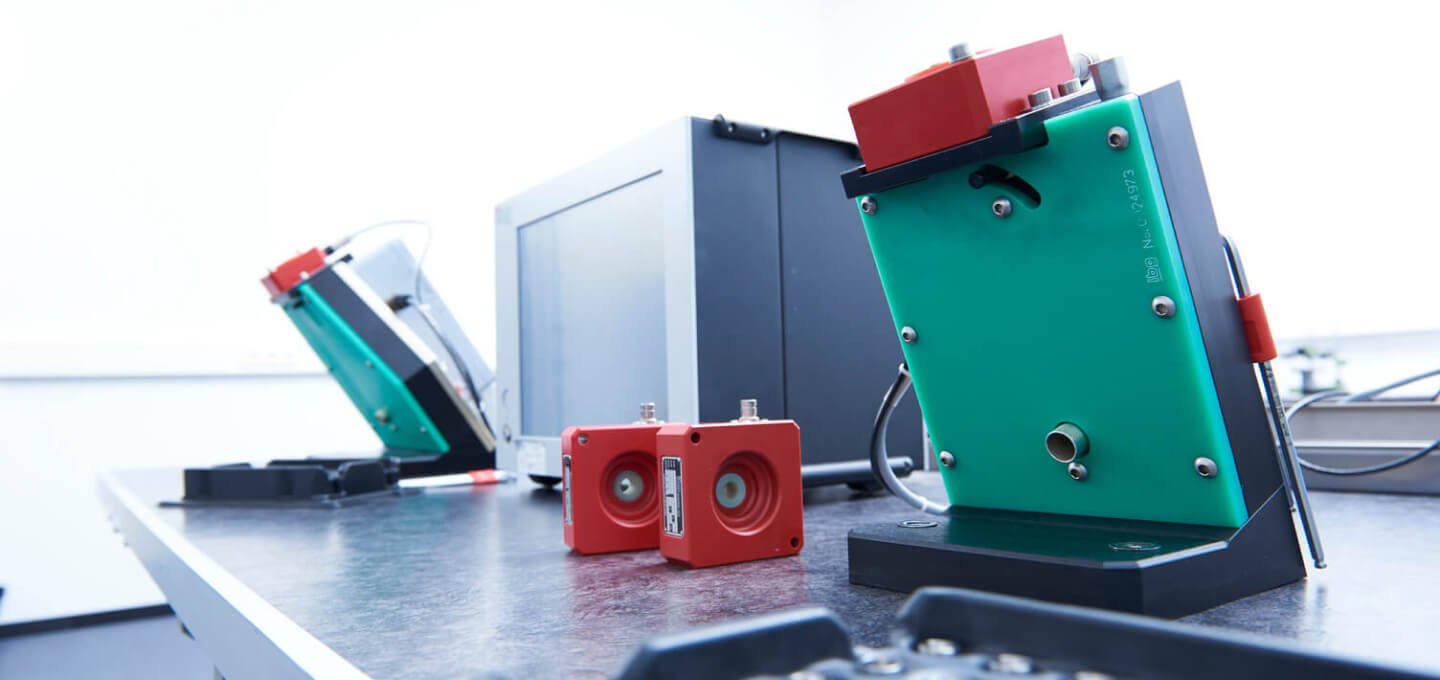

Eddy-current testing

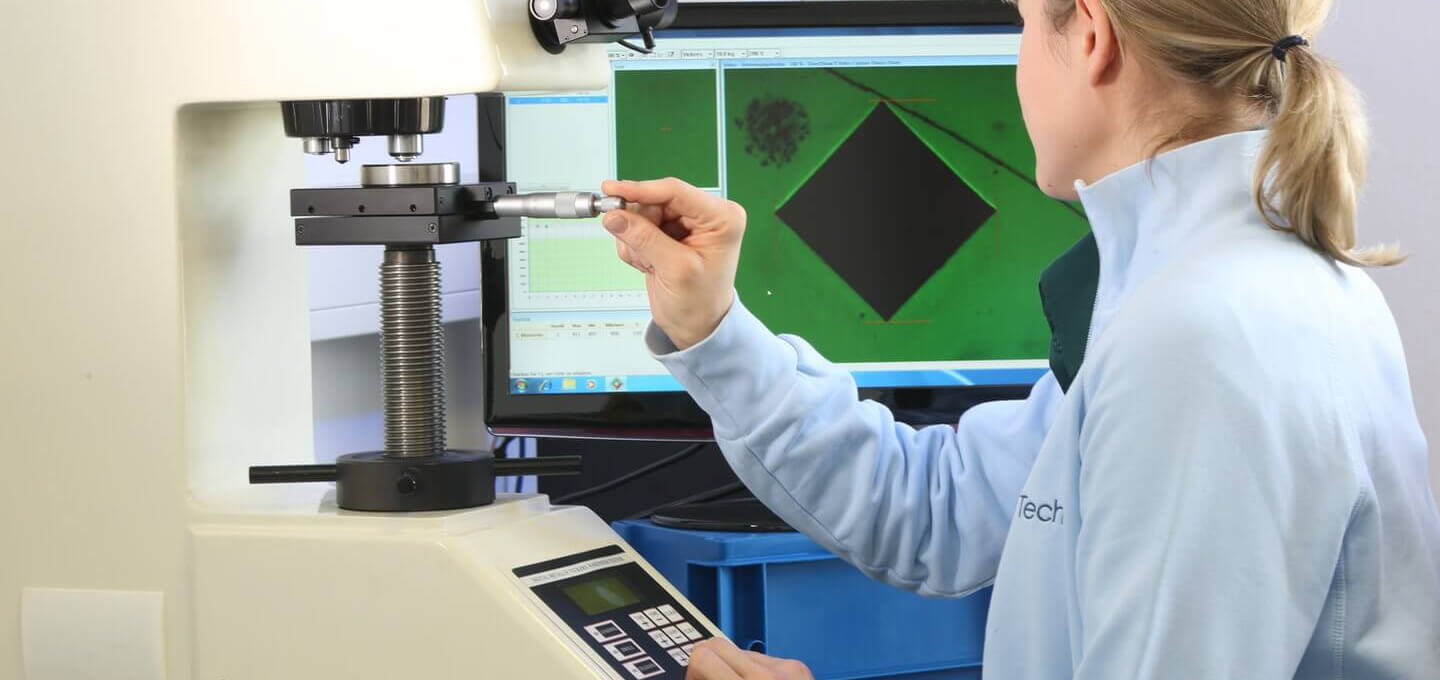

Hardness testing

Technomix supports you with precise visual inspections. We do this manually via magnifying glass, technoscope, endoscope or videoscope. Or in many cases we employ cutting-edge camera technology that is both fully automated and cost-efficient.

We inspect the surface of your components and parts for all types of damage, flaws and defects that may compromise their quality or functionality.

For jobs that demand precision down to millimetres or even micrometres, Technomix performs length measurements, run-out inspections, angle tests, gauging or other tests to ensure that the dimensions and shape of your product match all specifications.

We perform not only visual inspections, but also dimensional inspections either manually or, in many cases, using fully automatic camera technology.

For electrically conductive materials, we use eddy-current testing and electromagnetic induction to identify internal flaws or processing errors.

Cracks, flaws and other abnormalities cause a change in the magnetic field. This allows us to rapidly assess the properties and internal condition of the parts we inspect. We also use this method to determine the material thickness, layer thickness and the uniformity of elements such as welded joints.

Technomix is also expert in quantitative hardness testing using the Vickers method. This involves applying a load to the test specimen at specific points to assess whether the hardness of the material matches the specifications.

The method also allows material defects in the product to be analysed – for example after unexpected complaints.

Free, non-binding offers with quick response times.

Your benefits from our material testing

✅ Maximum reliability

100% adherence to delivery dates and schedules, as well as clear, dependable test results – so you minimise contract risks while also avoiding complaints.

✅ High test volumes and precision, even under time constraints

We even take on jobs at short notice if unexpected defects crop up or customers receive complaints that require quick resolution.

✅ Value for money

Thanks to innovative camera technology, we can visually and dimensionally inspect many test specimens fully automatically. You benefit from the same levels of precision, but at a lower cost.

✅ Improved processes

With our 30+ years of experience in quality assurance, we can help your company to improve in-house processes or even to develop your own cost-saving initiatives.

Some of our most satisfied clients

Still unsure about the benefits of material testing?

Technomix has been active and certified in quality assurance since 1987 in Germany, Europe and worldwide. We offer you straightforward processes, reliable assessments and smooth collaboration that, thanks to our high standard of service, also extend far beyond pure material testing.

Highly qualified inspection personnel and the most advanced inspection technology.

In particular when it comes to manual visual inspections, Technomix works with magnifications that far exceed the norm in the material testing branch. The technoscopes we use are the same as those used for surgical procedures.

Also unique to us is cost-efficient, fully automated material testing using state-of-the-art camera technology. We embody the values of innovation and progress – and continue to train our already highly qualified inspection personnel on an ongoing basis. These high standards translate into more safety and reliability for you.

Highly qualified inspection personnel and the most advanced inspection technology.

In particular when it comes to manual visual inspections, Technomix works with magnifications that far exceed the norm in the material testing branch. The technoscopes we use are the same as those used for surgical procedures.

Also unique to us is cost-efficient, fully automated material testing using state-of-the-art camera technology. We embody the values of innovation and progress – and continue to train our already highly qualified inspection personnel on an ongoing basis. These high standards translate into more safety and reliability for you.

State-of-the-art test lab.

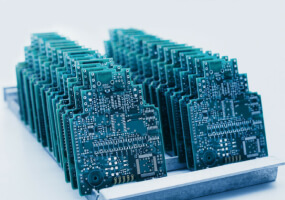

Technomix quality starts with perfectly lit, ergonomic work stations. We continually optimise our testing facilities using the poka-yoke method and our QM system. Our labs are equipped with dedicated inspection equipment for almost any test specimen, including electronically sensitive components.

We inspect these parts in a specially constructed and shielded ESD protected area with turnstile entrance and earth resistance tester. So whatever your product, Technomix is ready for it!

State-of-the-art test lab.

Technomix quality starts with perfectly lit, ergonomic work stations. We continually optimise our testing facilities using the poka-yoke method and our QM system. Our labs are equipped with dedicated inspection equipment for almost any test specimen, including electronically sensitive components.

We inspect these parts in a specially constructed and shielded ESD protected area with turnstile entrance and earth resistance tester. So whatever your product, Technomix is ready for it!

Inspection procedures

You have a choice of three inspection procedures – with easy-to-interpret digital inspection reports.

Reject goods test

A reject goods test functions as a last line of defence before you dispatch your products to your end customer. You provide us with a catalogue of possible errors or otherwise defined error criteria, and we inspect every individual part in your consignment. If and when a test piece displays even one of the predefined errors, it is immediately rejected. This ensures that your end customer only receives verifiably flawless parts and components.

Pareto test

A Pareto test differs from a reject goods test in that it includes all defined tests, even if a product has already displayed one of the defined errors. After testing, the digital test report details all of the identified errors and findings. This process is an ideal choice in various scenarios, e.g. for an upcoming safe launch phase, because it identifies and rectifies errors in advance. It is also suitable for damage analysis following complaints.

ABC test

The procedure for the ABC test is very similar to the Pareto test, except that identified errors are also weighted according to prevalence (A / B / C / etc.) It is suitable for the quick identification of possible error patterns so that these can be rectified in a targeted way.

Free, non-binding offers with quick response times.

A holistic range of services and logistics

Learn about how our extensive array of services and logistics can benefit your company. We can provide you with a wide variety of service and transport options either before or after the material tests.

FAQ

We’ll be happy to give you a non-binding quotation. Simply send us your sample parts, a technical drawing or an error catalogue. After we inspect the individual part, we can calculate the costs involved and ensure that working together with you is a viable option. The quotation then depends on a number of factors such as the quantity of test specimens, the number and complexity of inspections required, the packaging and the decision on whether to inspect your products using fully automated camera systems or manual inspection. Our experts look forward to discussing our material tests in more detail with you.

First, we discuss your product and specific errors or criteria. Ideally, you then send us rejected parts and good parts or technical drawings and images so that we can make a more detailed assessment. If necessary, we also perform a trial inspection to refine our inspection parameters. At this stage we clarify the general conditions with you and draw up a tailor-made quotation to meet your requirements. After final approval, we immediately start to compile inspection guidelines and error catalogues (if not yet available) and to brief our inspection personnel about the product. Finally, we start the series inspection of your product to ensure all your quality standards have been met.

We inspect a myriad of different components in a huge variety of sizes, types and shapes. They range in size from the tip of a ballpoint pen to a large turbine blade. We can accommodate pretty much any size of component and we are geared towards the specific needs of our customers. If you think your components may be too big or too small for our inspection process, just ask us! Together we can figure out the best solution for your needs.

Yes, that’s possible in principle, if for some reason parts and components can’t leave your factory. In this case, our experts help you find the best solution.

Technomix – representing high-precision quality assurance since 1987.

With 150 employees as of the end of 2020, Technomix is one of Germany’s largest companies in the field of visual and dimensional inspections and material testing. We specialise in the automotive and aerospace industries.

From our locations in Pommersfelden and Plzen (Czech Republic), we inspect up to 200 million parts annually, continuing to make great strides in innovation and boasting the very highest standards in personnel training and process optimisation.

Interested in

collaborating with us?

We’d love to hear from you and will get back to you as soon as possible.