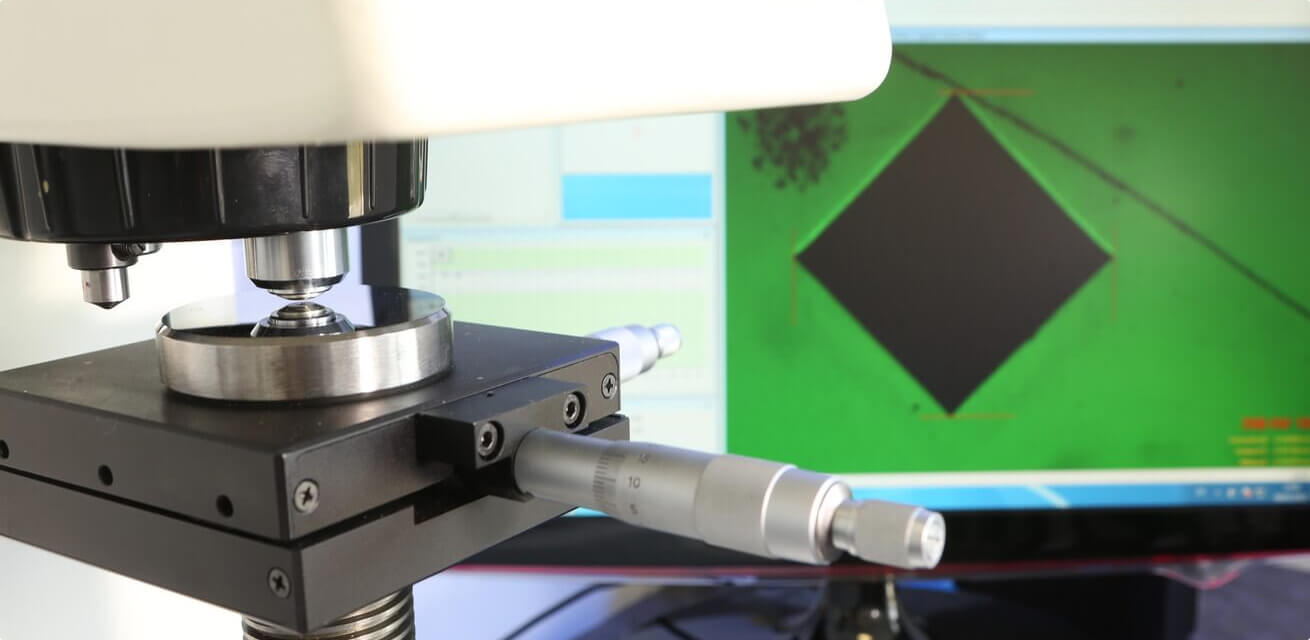

The Vickers hardness test was developed by Vickers Ltd. back in 1925. The test setup is simple. A very small, inverted diamond pyramid with a square base and an apex angle of exactly 136 degrees is pressed vertically into the surface of a test object. (Apex angle = angle of the opposing sides of the pyramid with respect to one another.) After this, the indentation depth of the pyramid and a special hardness value formula (“Vickers hardness”) can be used to determine the density and stability of the product.

Metal manufacturing companies regularly use the hardness test to ensure that their products can be further processed without defects or breakages, and to prevent contractual risks and complaints. It is important to emphasise here that the hardness test is normally a quantitative process, meaning it is not carried out on every part. A series inspection of the internal condition of a product can also be done using non-destructive eddy-current testing.

Trust in our company’s high quality standards and straightforward processes and find out how hardness testing and other material tests can make complaints and their associated contract risks a thing of the past.

For products, a hardness test is a form of stress test. Hardness testing can be described as either static or dynamic. At Technomix, we always use the static testing method for your products.

→ Static hardness testing: The test load is applied constantly, or increased, until a predefined minimum time of force application has been reached. For a test piece that will be subjected to and must withstand constant force application in its ultimate use, the hardness test is also suitable as a simulation, irrespective of the general hardness and stability result (based on the indentation depth).

→ Dynamic hardness testing (impact testing): This involves ascertaining how much impact force a product can withstand. The hardness of the material is calculated by measuring the energy required for the pyramid tip to indent the material and then withdraw again.

Which of the two test types will be relevant is determined by the product’s material and the desired insights of the testing.

Technomix is regularly enlisted by companies, predominantly from the automobile and aerospace industries, that want to ensure that their customers receive only flawless products. The Vickers hardness test is just part of our extensive range of services. Tell us what you require today and become one of the many satisfied customers who trust in the extraordinary levels of precision and reliable appraisals of our highly qualified inspection personnel.