Through the crust and into the test piece’s mantle and core: No other non-destructive testing method allows the internal condition of a test specimen to be inspected so quickly. Microscopic cracks, pores, grinding burns and other irregularities both close to or on the surface, and inside the test piece, can be detected immediately.

At the same time, the test provides specific information about whether the thickness, hardness, and structure, as well as the strength, heat treatment and alloying of the material and its individual layers meet the specifications.

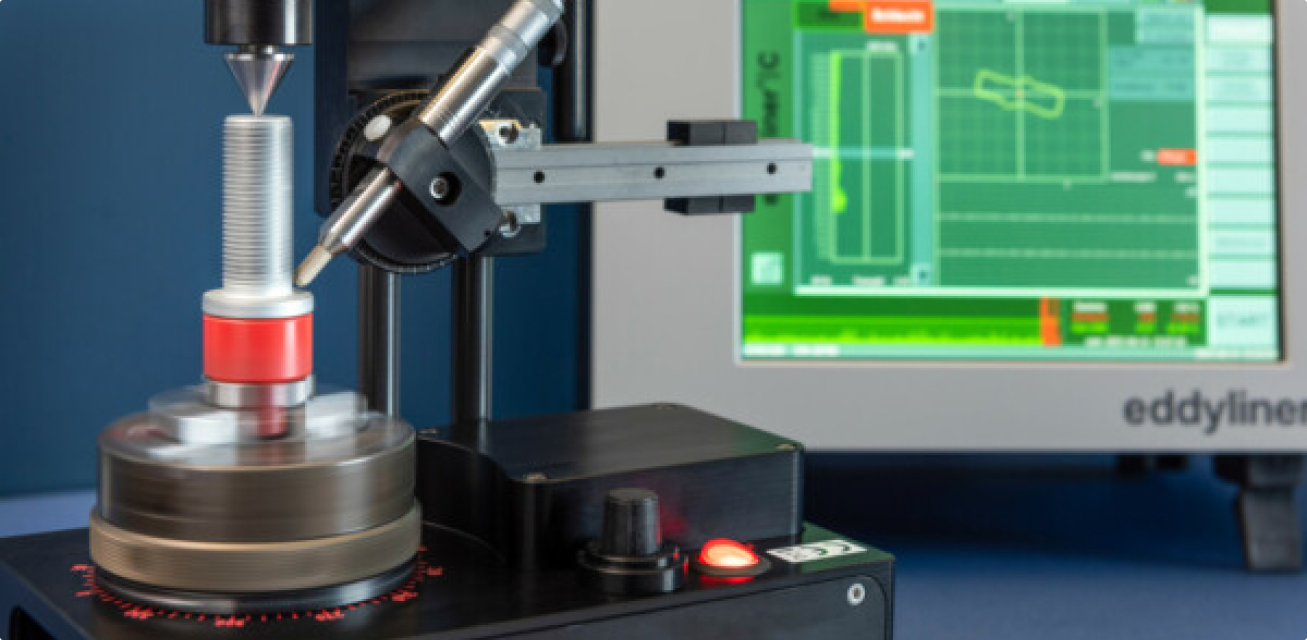

Trust in our company’s high quality standards and straightforward processes and find out how eddy-current testing and other material tests can make complaints and their associated contract risks a thing of the past.

In short, with a voltage source and an electric coil. The voltage source generates an alternating current. This creates an alternating magnetic field around the coil. If an intact, conductive object is then passed through the coil, this induces an eddy current on the object, which generates a second, equal alternating magnetic field, always opposite to the magnetic field of the coil.

The trick to eddy-current testing is that the magnetic field of the eddy current changes when damage, imperfections, and changes in material properties such as hardness or permeability interrupt the even flow of current. If there are cracks, for example, the eddy currents look for a way around the crack. This immediately becomes apparent and indicates that there is a flaw in the material. In the case of alloys, the same thing happens if the metal compounds are imbalanced.

In tests, these types of changes and their intensity are crucial when it comes to judging whether the material is free from defects and whether it matches its material specifications. Manufacturing companies can thus use eddy-current testing to ensure that their products are in a flawless condition.

Technomix can also arrange for the reshipment of intact parts to the end customer after eddy-current testing. This means we are the final quality assurance step between production and further processing on the customer’s side. (This is also referred to as screening inspection.)

A complex electromagnetic procedure for clear and precise results: Technomix is regularly enlisted by companies, predominantly from the automobile and aerospace industries, that want to ensure that their customers receive only flawless products. Eddy-current testing is just part of our extensive range of services. Tell us what you require today and become one of the many satisfied customers who trust in the extraordinary levels of precision and reliable appraisals of our highly qualified inspection personnel.