For some parts and components, millimetres or even micrometres dictate whether they can be processed further as intended, and whether they can properly perform their function. Dimensional inspection helps to ensure this. It helps to prevent complaints and the contract risks and reputational damage that go along with them, as well as enabling error patterns to be recognised and manufacturing processes to be optimised.

In the automotive industry in particular, dimensional inspection is used to test the repeatability of processed products. Alongside visual inspections and other forms of material testing, dimensional testing is part of the quality assurance arsenal in manufacturing companies.

Trust in our company’s high quality standards and straightforward processes and find out how dimensional inspections and other material tests can make complaints and their associated contract risks a thing of the past.

Forged parts, bars, pipes, bent parts, stamped parts… the list of components whose dimensions need to be absolutely exact for further processing is nearly endless. And all the while the quality standards in the industry are rising. Every single year. But there comes a point when random sampling is no longer sufficient as a means of safely ensuring the quality of parts and components.

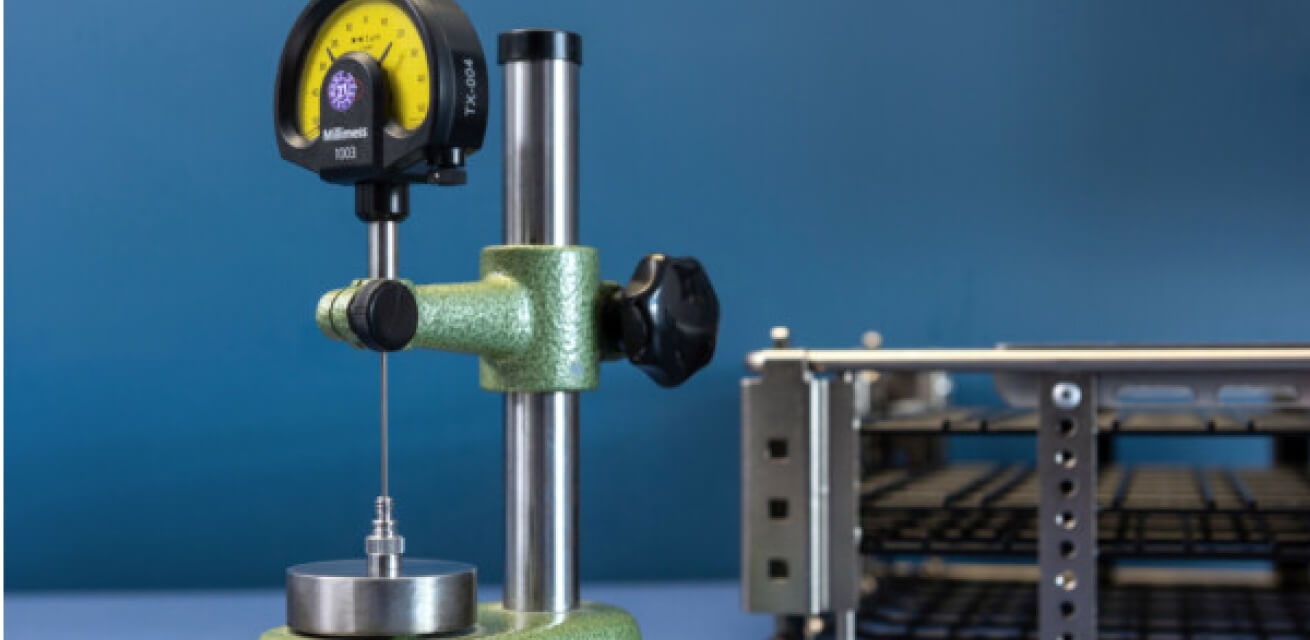

Ideally, dimensional inspections should be carried out on a piece-by-piece basis during ongoing production. Therefore, companies who cannot do this in-house need reliable partners that can offer outstanding logistics and high clock speeds with consistently high precision. This is where Technomix comes in. To accurately ensure the correct dimensions of your products, we use cutting-edge instruments ranging from optical-mechanical auxiliary devices to ultra-modern laser systems, through to fully automatic camera technology.

→ Length measurement

→ Width measurement

→ Width measurement

→ Cross-section measurement

→ Gauging (tolerance range)

→ Surface inspection

→ Concentric running tests

→ Micrometre testing

→ Angle testing

→ …

We will provide you with a definitive appraisal on whether the basic dimensions, wall thicknesses or distances between individual parts of your product match their specifications. This will also allow you to ensure that the surface of your product is in flawless condition and doesn’t have any undesired roughness.

Technomix is regularly enlisted by companies, predominantly from the automobile and aerospace industries, that want to ensure that their customers receive only flawless products. Dimensional inspection is just part of our extensive range of services. Tell us what you require today and become one of the many satisfied customers who trust in the extraordinary levels of precision and reliable appraisals of our highly qualified inspection personnel.